Site Six’s M.A.N.E Makerspace

Designing a next-generation makerspace for Columbia Engineering that champions flexibility, creativity, and collaboration at the core of its environment

Human Centered Design and Innovation

1. Challenge

Columbia Engineering’s current makerspaces and labs are:

Cramped and fragmented

Siloed by department, limiting collaboration

Inefficiently organized and hard to navigate

Noisy, windowless, and uninspiring

Lacking dedicated areas for quiet teamwork and loud fabrication

Not future-ready for hybrid or tech-integrated learning

“Departments don’t talk to each other. We just buy new parts instead of sharing.”

- Mechatronics Lab Technician

“We don’t have space to build and meet in the same place.”

- CS Senior & Teaching Assistant

“We need a space actually designed for engineers—with good equipment and space to think”

- PhD Student

2. Target User and Stakeholders

Target User: Engineering Students

Undergraduate or Graduate Student

Active in hands-on courses or clubs (FSAE, CSI, Columbia Robotics)

Works on projects like robots, vehicles, physical prototypes

Needs access to machines, tools, and a workspace

Balances build time with team meetings

Stakeholder Ecosystem

Faculty & Student Teaching Staff: Use space for labs, capstone mentoring, and office hours

Student Clubs & Organizations: Organize builds, meetings, and project showcases

Research Teams & Assistants: Access tools, machines, and collaborative spaces

Facilities & SEAS Admin: Maintain safety, manage scheduling, oversee equipment

Alumni & Donors: Fund projects, offer mentorship, suggest innovation visibility

3. Primary and Secondary Research

Interview Key Findings:

Room for Improvement: Lack of natural light, cramped and crowded–especially from frequently brought in tour groups, limited access to high quality equipment for non mechanical engineering students, scattered resources on different floors–inefficient for projects that utilize different types of equipment, noise concerns are something to consider

Positive Aspects to Maintain: High quality equipment, lots of resources to teach equipment use, collaborative environment, community space, popular space for interdisciplinary use

Better Design of a Future Engineering Lab: better natural light and open spaces, make it feel less isolated, expand/improve access to equipment for all students, more integrated lab layout (minimize movement between floors), optimize space for collaboration, noise management wall system with partial enclosures or soundproofing to keep machinery accessible but not where the noise takes over the entire space

Secondary Research Findings:

Collaboration is the key of future education, major switch from lecture hall learning to active and involved learning spaces, spaces for technology integration, adaptability, accessibility bhdp.com

Flipped learning is also a key focus for the future of education. Flipped learning aka inverted learning part of all of direct instruction is online and the class time is used for collaborative hands on learning. Increases opportunities for peer interaction and deeper engagement with the material. bera-journals.onlinelibrary.wiley.com

Flexibility in learning spaces: furniture, chairs, storage, room dividers. This is for the purpose of providing freedom to decide what time of learning is best for the given activity. Less is more, kind of minimalist design because it is a given that there is already a lot of equipment taking up a lot of space. Ability to shift the type of learning whether it be frontal, instructional, or collaborative work. build-review.com, buildingstudio.com

Movement in a space to not feel so cramped and crowded, avoid isolation from outside or external spaces, natural light, lots of airflow, nature inspired spaces promote creativity, open floor plan while maintaining privacy in research, able to be a space where different disciplines can learn. cmmonline.com

Problem Statement:

Columbia’s current makerspaces and teaching labs are fragmented, overcrowded, and poorly connected across the Mudd building. This physical and organizational separation limits collaboration, cross-disciplinary learning, and creative exploration. Many spaces are tied to specific majors or floors, reinforcing silos and making it difficult for student clubs and independent projects to access the tools and support they need. As a result, creativity is stifled—not due to lack of talent, but because of constrained environments that discourage experimentation, knowledge-sharing, and the fluid exchange of ideas

4. Ideation

Idea^1: Flexibility and Multi-functionality

This makerspace features flexible walls for modular reconfiguration, anchored by fixed technical zones. It supports classrooms, meeting rooms, and open collaboration, adapting to shifting needs.

Green (Non-Movable):

Fixed rooms for machine tools, 3D printers, and electronics. These require stable infrastructure and stay in place.Blue (Classrooms): Modular spaces for teaching, training, and workshops. Adjustable as needed.

Red (Meeting Rooms): Four flexible rooms for meetings, clubs, and student orgs.

Central Working Space: Open, adaptable area for group work, club activity, and events like Senior Design Expo. Can also be space for visitors and guests.

Idea^2: Functional Separation and Purpose-specific Zone

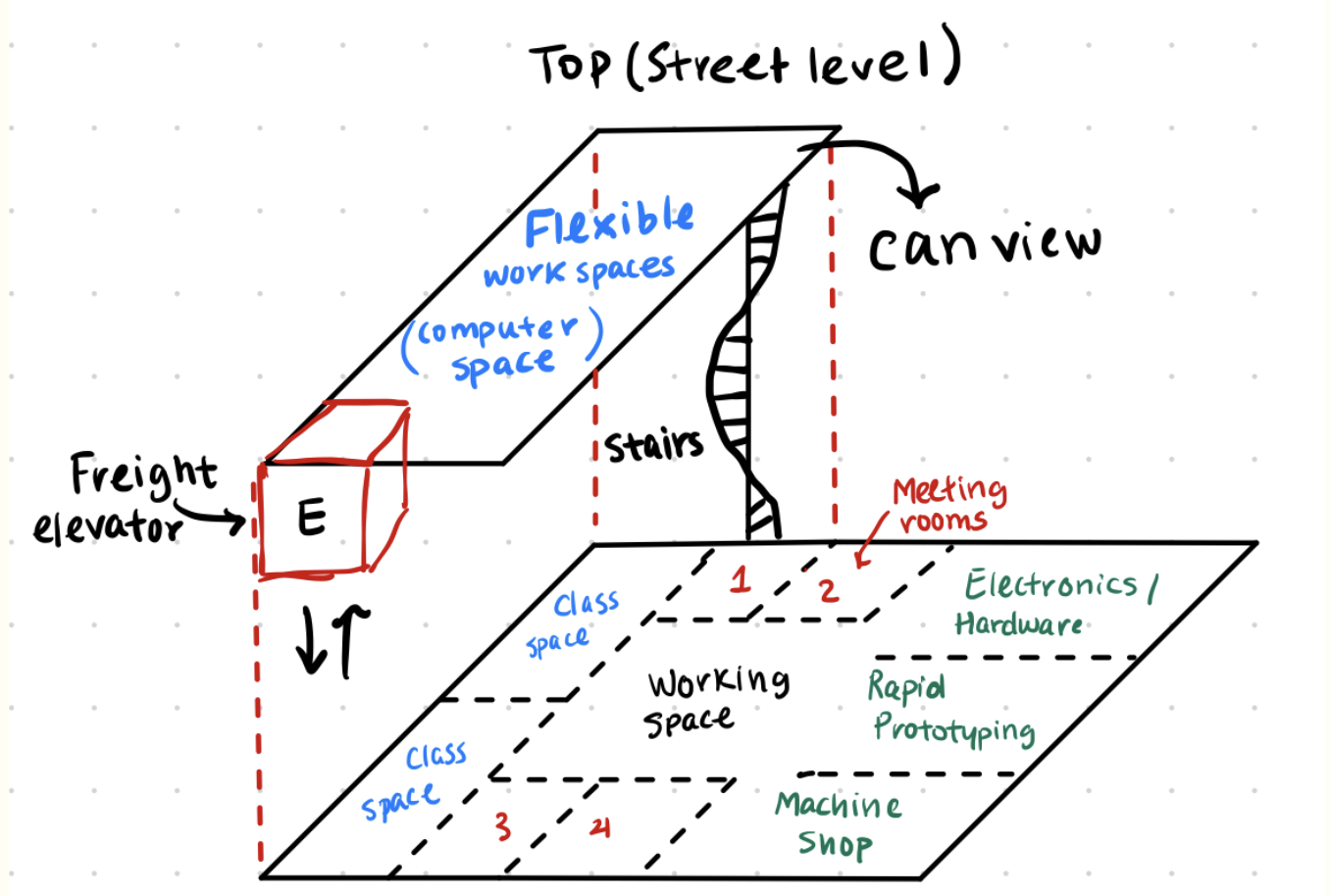

This design is an expansion of the first makerspace concept. The first floor remains the same, with fixed machinery, electronics, classrooms, meeting rooms, and modular working areas. A new second floor (loft-style) is added above, visible from the ground floor.

Second Floor (Loft): Flexible workspaces focused on computer-based work which is ideal for student clubs managing both physical builds and digital modeling/tasks (e.g., FSAE, Senior Design, CSI).

The floors are connected by stairs and a mini freight elevator for moving large parts and equipment (e.g., car parts, prototypes, large assemblies).

Purpose: Promotes better workflow separation–hands-on building downstairs, digital and planning work upstairs–without splitting teams across buildings or rooms that are too far away. Also grants staff members and visitors with a birds-eye view of the large space for safety and promotional wow factor.

This makerspace layout is clearly divided into functional zones to support different types of activities. A Social/Teaching Area provides space for collaboration, learning, and youth-friendly activities, and a Silent Area supports quieter work like coding and electronics.

There are dedicated storage areas, tools zones, and support spaces for companies, nonprofits, and a small shop offering materials and refreshments. Circulation is designed for smooth flow across all sections.

Idea^3: Scoutbots PolyU Makerspace

5. Evaluation

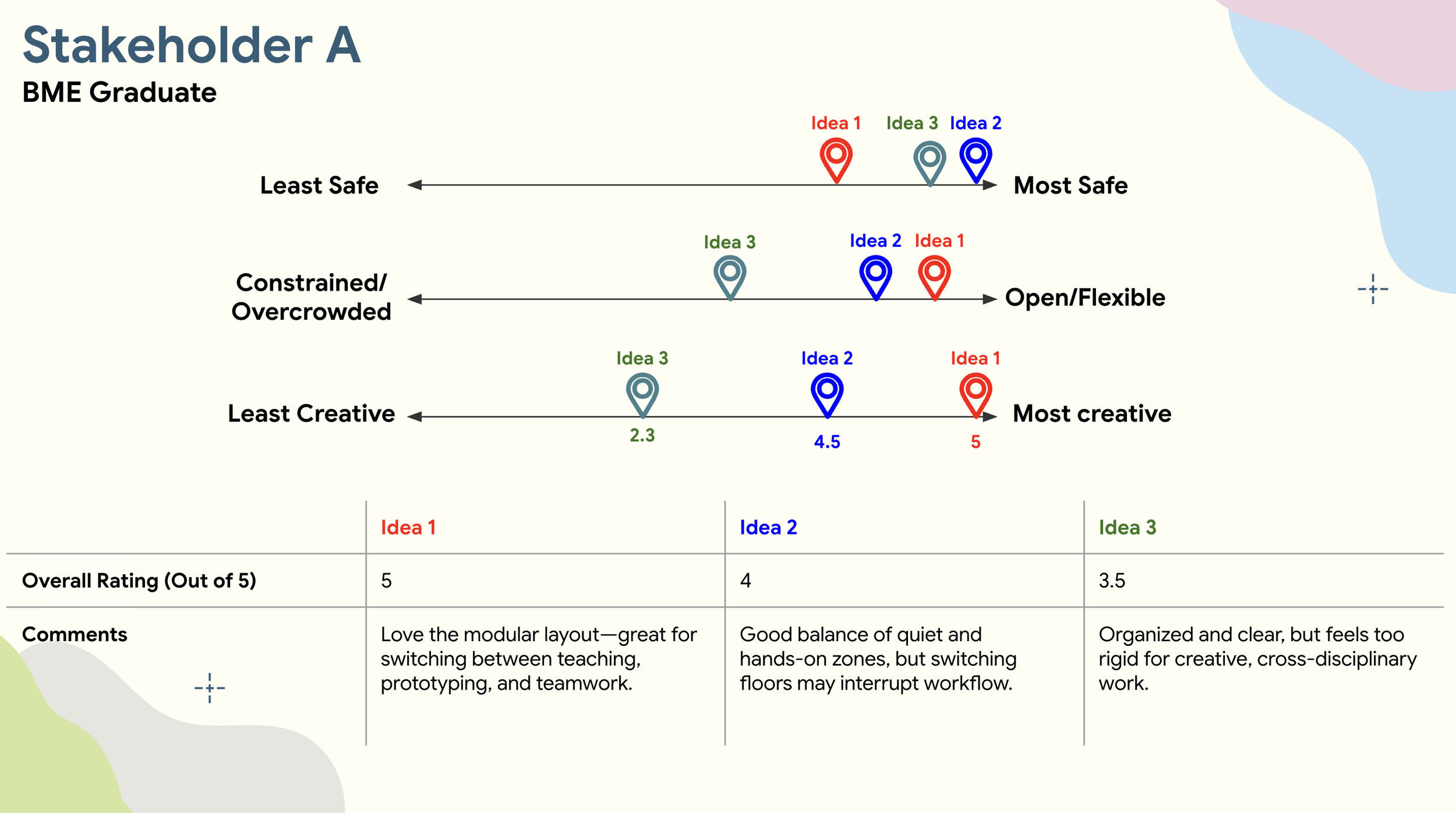

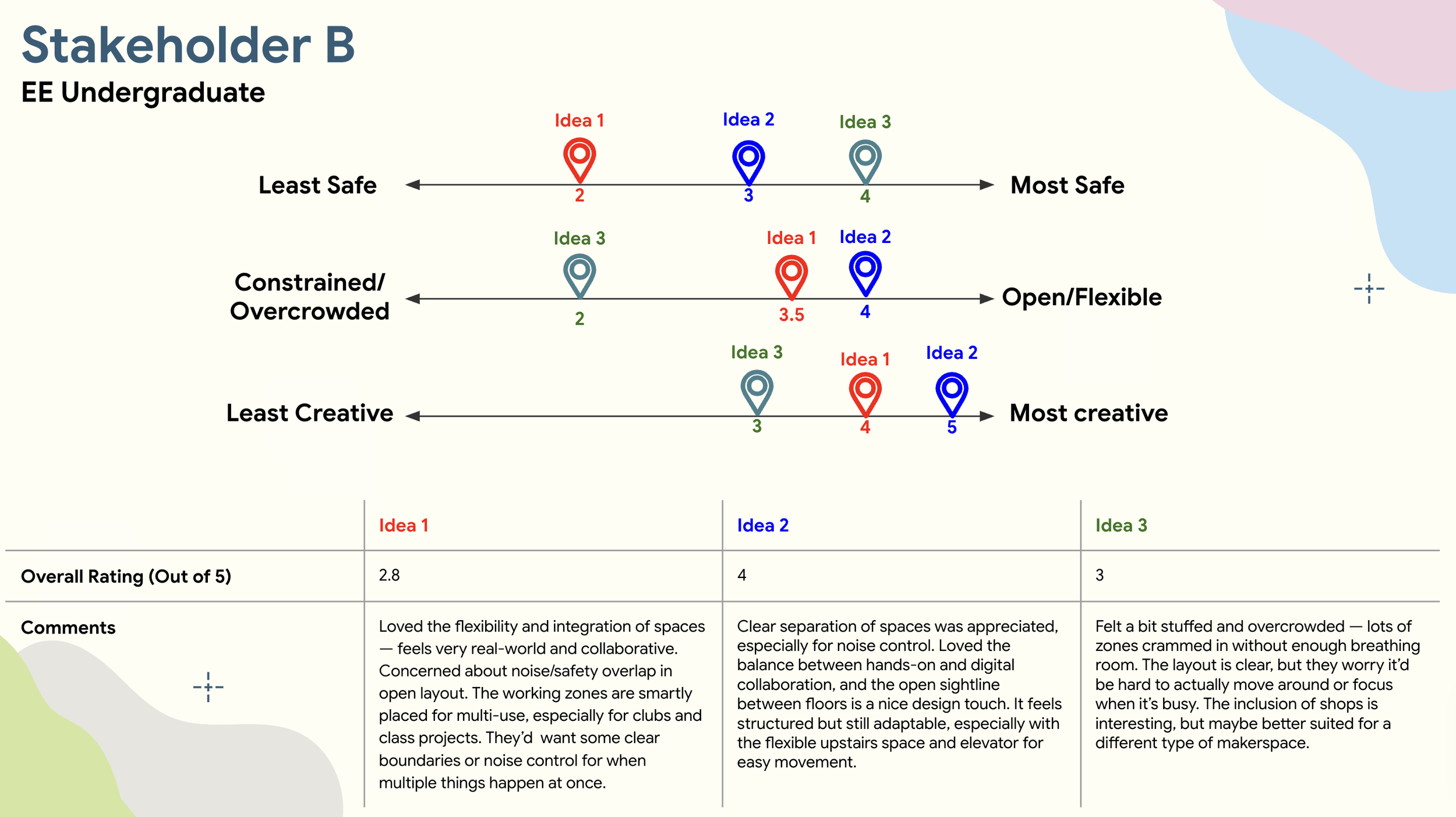

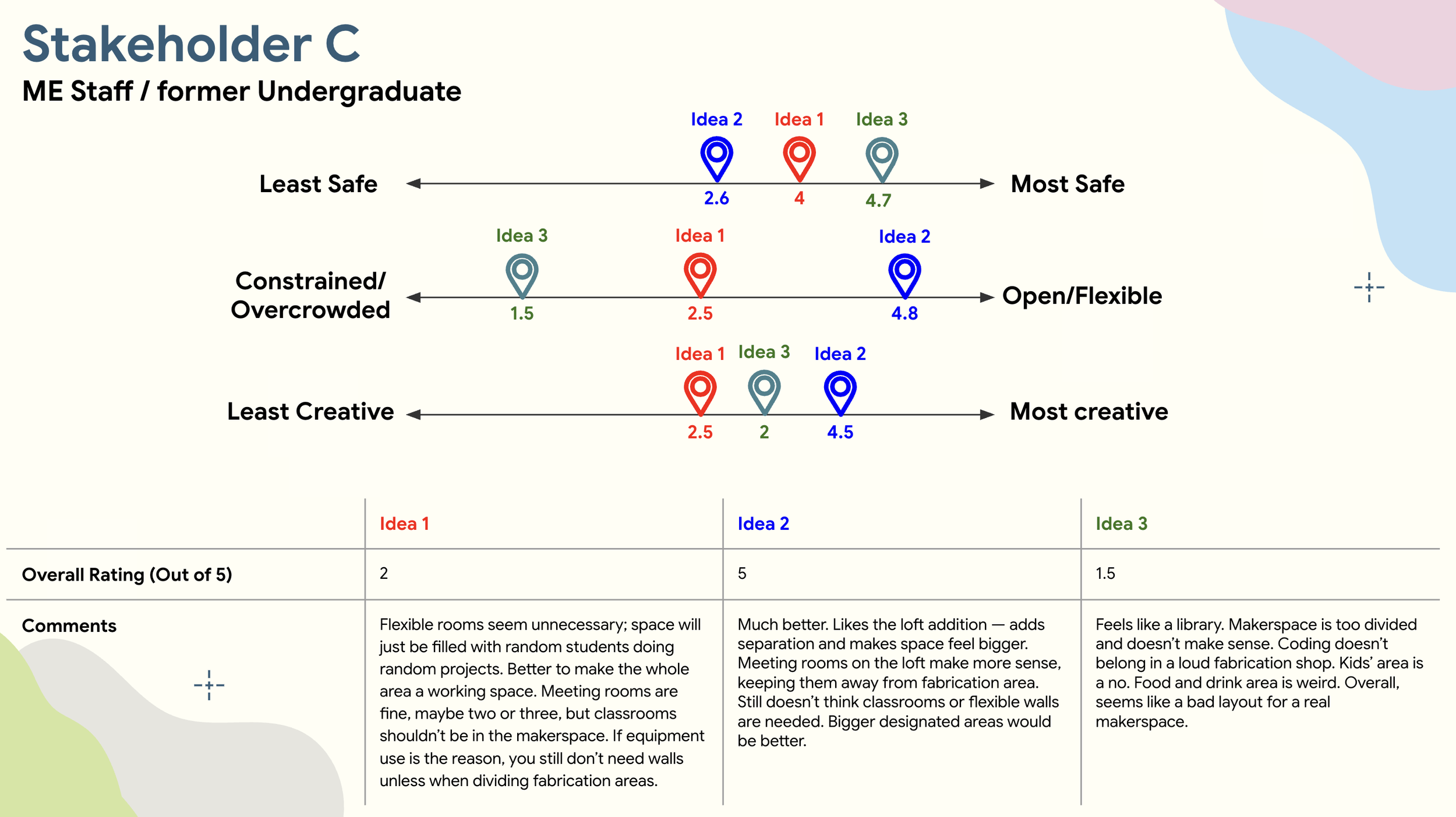

We evaluated three design concepts using stakeholder feedback from a BME graduate, an EE undergraduate, and a former ME undergraduate staff member. Each was asked to assess the ideas based on safety, flexibility, and creativity, using visual scales and a 5-point rating system.

Across all three stakeholders, Idea 2 consistently scored highly for its clear layout, separation of spaces, and balance between quiet and hands-on zones. It was especially praised for its organization and thoughtful vertical flow. While Idea 1 was recognized for its flexibility and collaborative feel, it raised concerns about noise and spatial overlap. Idea 3 was seen as overly rigid and crowded.

Based on this feedback, we chose to move forward with Idea 2 as our primary direction, incorporating modular elements from Idea 1 to enhance adaptability.

6. Pitch & Prototype

Making is central to engineering—it’s how students collaborate, build, and innovate. Columbia’s student groups and research teams drive real-world impact but lack a unified space that matches their contributions.

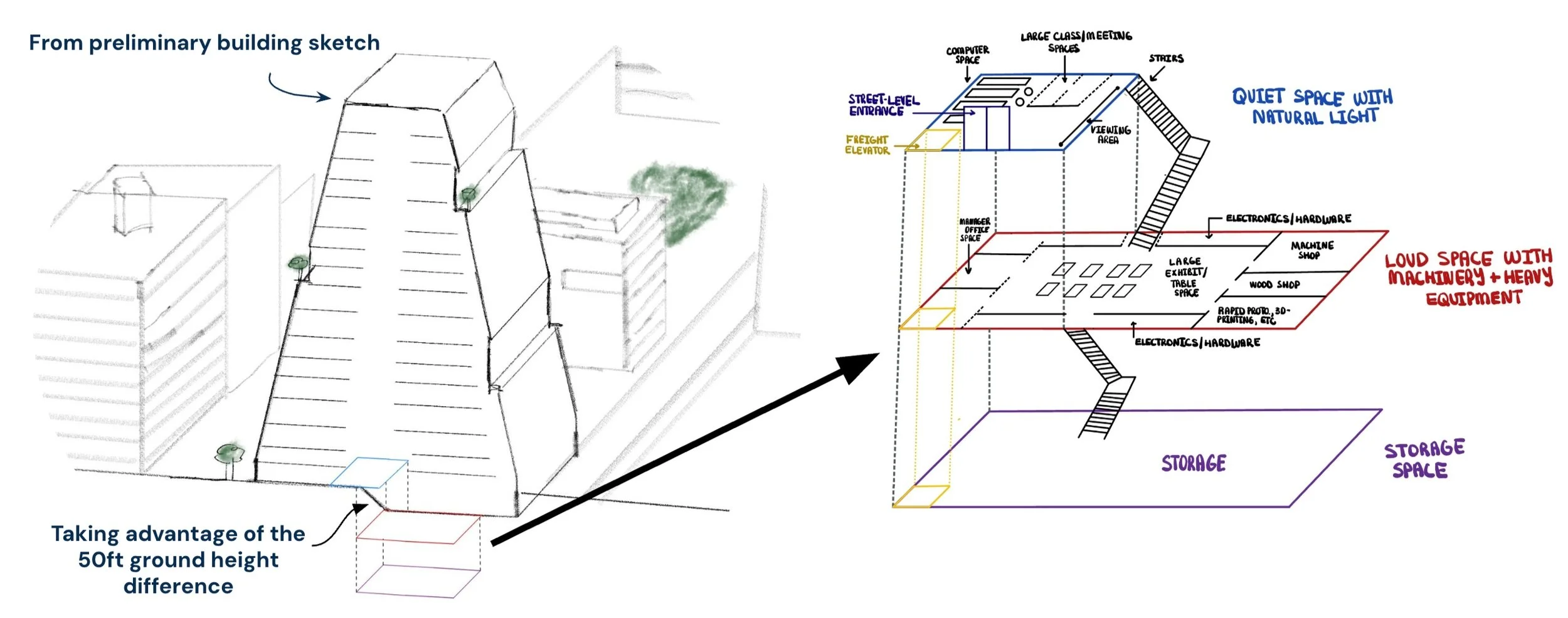

Our proposed makerspace changes that. Spanning three levels, it places collaboration areas with natural light at the top, heavy machinery on the middle floor, and storage below—all connected by a dedicated elevator. This layout maximizes space without using valuable street-level real estate.

Open to all majors and degree levels, this makerspace fuels creativity, strengthens teamwork, and positions Columbia Engineering at the forefront of student-driven innovation.

A space to support every step of the engineering journey

7. Futurism Design Video

Here is our vision taken to the extreme. We put aside today's constraints and conventional expectations and show an ideal solution we believe will be possible in the life of the new building in 50 years' time.

8. Final Design Video

This design proposal was part of a Human-Centered Design and Innovation course at Columbia Engineering. After presenting various ideas, the M.A.N.E. Makerspace concept won 1st place, highlighting its potential to revolutionize engineering education spaces